CableTrack

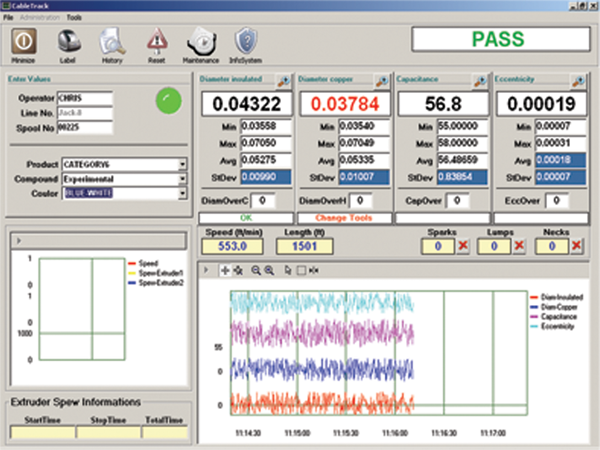

CableTrack is a powerful and reliable detection software, capable to communicate with most of the devices specialized in the Wire&Cable industry: BetaLaserMike©, Zumbach©, Sikora© and others. It’s an integration of existing detection devices with real-time processing of information software against Engineering, QA and Production control criteria.

CableTrack is a real-time data acquisition system that allows to read, analyze and monitor the information coming from the insulating and jacketing lines. It gives the ability to proactively monitor your process variation, to follow your output and to take accurate decisions.

Additional Options

- Provides an intuitive user interface and incredible flexibility whether you are an engineer, manager or operator.

- It allows continuous detection and analysis against pre-loaded criteria (diameter, capacitance, concentricity, lumps, sparks, line-speed, downtime, uptime, min, max, avg., stdev., etc.).

- Provides enhanced trending-chart capabilities to monitor several different readings.

- Triggers alarm requesting corrective actions. When a rule violation occurs, the system will immediately display the fault and raise an alarm to operator.

- Save the footage where the fault occurs (makes the repairing process more accurate and faster).

- Accurately display the right information in the right format.

- Electronically display the manufacturing process-instructions.

- Automatically prints the labels for every spool produced.

- 100% manufacturing oriented.

- It shows operators PASS/FAIL and the corrective actions to take.

- Provides a comprehensive spec-management tool that gives the ability to manipulate easily specs, and products.

- Empowers you to deploy and merge different detection devices from different manufacturers.

- Provides enhanced trending-chart capabilities to monitor, real-time, several different readings.

- Full traceability capabilities.

- All the readings are saved and could be exported to EXCEL for further analysis.

- Every reel produced is identified and can be traced at the final manufacturing process.

- The system has the capability to ‘send a flag’ to the process and R&D engineer when an experimental product is done.

- The system can process old data against new specs criteria.

- Easy to retrace the source of a failure due to customer’s complains.

- It allows extrusion operators to adjust their line as soon as a problem is detected.

- Production efficiency reports and other output calculations based by products, operators, work-shift. (Uptime, DownTime, BleedTime, LineSpeed, Min, Max, StDev, Avg, Pass/Fail, Length produced, etc.)

MRP Solutions

Other Software